The REA LabelTower is a complete solution for measuring code verification according to ISO standards and layout control. It verifies label layouts and contents of packaging and products for completeness, correctness, readability and presence even before production starts. Only when codes, fonts and layouts have passed the inspection is production released - no errors, no costs!

Layout and code verification even before the start of production. Digital image processing combined with artificial intelligence is the innovative solution for quality control - more efficient and reliable. Layout and code verification is already completed before the start of production. To do this, the software learns any size of product range by scanning sample sheets and defining individual labels and data.

If production is now to start, all the necessary data is compared with the stored sample sheet from the database for checking purposes. In case of discrepancies, an error is reported, which can thus be corrected before production starts.

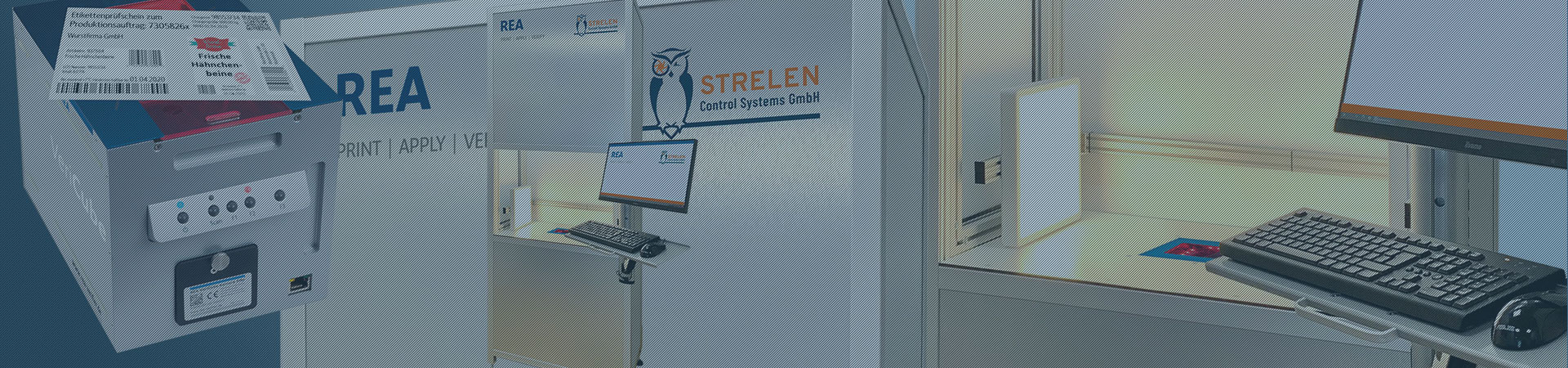

Together with the expert for image processing and automation Strelen Control Systems GmbH we offer a complete solution - the REA LabelTower. The layout check by Strelen Control includes a plain text check, a check of graphic elements as well as variable data. Code verification by REA VeriCube verifies code properties, contrasts and printing precision.

Matrix Codes (2D):

Barcodes (1D):