Both the REA VeriCube DPM and REA VeriCube DF are state-of-the-art 1D barcode and 2D matrix code verification devices that can verify code quality on reflective, mirror or glossy surfaces.

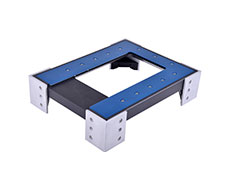

The REA VeriCube DF is characterized by its diffuse illumination, which casts a uniform and soft light on the surface of the product to reliably verify inspection parts with reflective and shiny surfaces.

The geometry of the inspection item is irrelevant. Even complex 3D geometries, where there is a risk of shadows being cast in the area or directly onto the code, are reliably verified. Shadows and extraneous light, which previously made code verification difficult, are no longer an issue. The result is reproducible and reliable measurement results.

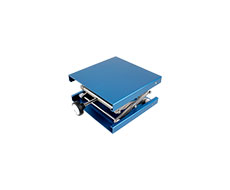

Even more diffuse illumination is achieved with the REA VeriCube DPM. With the integrated DOME illumination, directly marked codes can be reproducibly and reliably verified even on high-gloss and highly reflective surfaces. This is achieved by a matte white tube in the measuring chamber, of the code verification system. Just as with the REA VeriCube DF, 3D geometries, shadow formations and extraneous light influences play no role in the quality evaluation and the measurement results.

The coding quality of the direct marking is determined by both the REA VeriCube DF and the REA VeriCube DPM according to the DPM test method ISO/IEC TR 29158. Poor first-pass reading rates are thus quickly detected and the print quality of the code can be optimized.

2D Matrix Codes:

1D Barcodes:

Optional Codes:

Data structures and code properties:

Evaluation:

You have questions? We would be pleased to call you back.