"Professionals" present new coding and marking solutions

Fachpack innovations from REA Elektronik now also as video - the highlights

Mühltal, October 15, 2021 - At Fachpack 2021, REA Elektronik presented its latest developments under the motto "Print | Apply | Verify". Those who were not able to join one of the first live trade shows in a long time can now watch the news of the specialist for marking and code verification: The latest video of the "REA Marking Professionals" is online since today. The highlights at a glance.

For the first nine episodes of their video series, Daniel Wege (Business Development Manager) and Frank Debusmann (Sales Director national Coding and Marking Systems) travelled all over Germany for interesting applications of REA Coding and Marking Solutions. In the latest video, they present the highlights of the REA booth at Fachpack to their audience. The most important ones in words and pictures.

REA JET HR: Printing labels directly onto foil

Direct printing instead of labeling is now also possible on foils and smooth surfaces: The new, contact-free direct printing technology for the high-resolution REA JET HR systems prints codes and clear text with optimum contrast - even on transparent packaging foil. In a single step, the system creates a white ink mirror and immediately prints on it with black ink, or in color if required. The ink mirror and marking then dry together.

The new direct printing technology ensures high-contrast marking for excellent code quality and first-pass read rates. Elimination of labels reduces process costs. Elimination of carrier foil eliminates waste. Direct printing ensures that the packaging material is of the same type, which simplifies recycling - all in the sense of sustainable production and resource conservation.

REA LabelTower - Inspection of plain text and code quality on labels in one step

The new REA LabelTower uses an innovative combination of technologies to verify label content and the quality of 1D/2D codes in a single step. The new development is particularly interesting for all companies that label a lot and that provide their products with labels in different languages for export.It is the result of a cooperation between code verification specialist REA Elektronik and Strelen Control Systems GmbH, an expert in image processing and automation.

The LabelTower verifies the layout, fonts, and graphic elements of the label and compares them with the target specification to avoid the risk of confusion and incorrect labeling. At the same time, it verifies the properties of the printed code in terms of legibility, contrast, printing precision and standard-compliant quality.This ensures font and code quality and guarantees a high first-time read rate at the point of sale.

REA JET FL Laser Marking Cabin with Autofocus Function

The new laser marking cabin for high-quality marking of materials can be individually customized thanks to its modular design - at the price of a series product. The extremely versatile concept enables solutions ranging from stand-alone manual workstations to fully automated, networked marking stations. With the autofocus function in combination with the motorized Z-axis, users can work much more efficiently with frequently changing component geometries and reduce the risk of rejects. The cabin design and pulsed fiber laser also provide maximum flexibility for reproducibly producing high-quality product markings on plastics, as well as metals or ceramic materials. For this purpose, the REA JET FL Laser Marking Cabin can be optimally adapted to the customer's needs - from the size of the process chamber to the laser power and the placement of the marking field to the type of material supply and removal.

REA VeriMax Inline: Good to know that all is right

REA VeriMax Inline: Good to know that everything is right

Trust is good - control is better: The new REA VeriMax Inline Verification System was developed especially for companies that need to prove the quality of their 1D or 2D codes conforms to standards. Thanks to its small dimensions, the system can be installed directly in production lines. In proven verifier quality, it verifies up to 5 codes per second without contact in an uninterrupted inline verification.

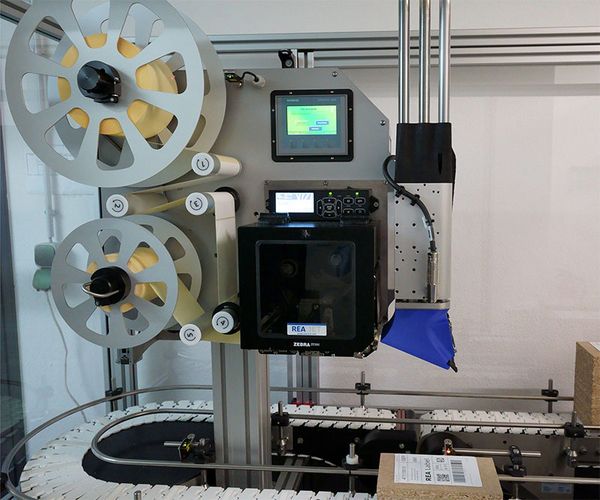

Flexible shipping labeling with the REA LABEL High-Speed Servo Labeler

The innovative REA LABEL High-Speed Servo Labeler combines the proven high print quality of REA LABEL Print and Apply Systems with automatic product recognition and speed. The servo-electric applicator places shipping labels quickly and precisely on cardboard boxes and packages of different heights - up to 2,500 products per hour. This makes it ideal for mail order and end-of-line applications with different sized packages.

When speed is less important than flexibility in label placement, REA LABEL's new 3-sided pallet labeler is the right choice: At standstill, it optionally places labels over up to three sides of the pallet.

Previously published videos of the series "REA marking professionals on site":

Episode 1: Building materials industry

Episode 2: UDI & MDR

Episode 3: Industry 4.0

Episode 4: Marking FFP2 masks

Episode 5: Laser marking of plastic

Episode 6: Food marking 1

Episode 7: Food marking 2

Episode 8: Bag marking in the bulk materials industry

Episode 9: Track & Trace Application